You’d be forgiven for being confused if you don’t know the difference between process, SOPs, and work instructions.

For starters, let’s start with the overall objective of all these documents. Essentially, they all aim to improve a business’s efficiency and quality of work. But they have different functions in order to help do that.

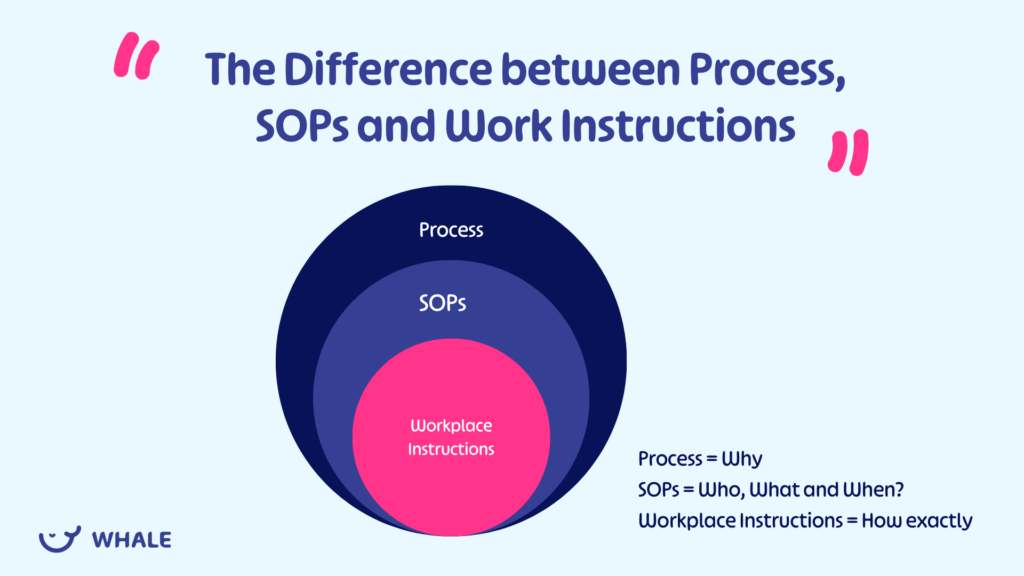

If you look at a business from a new employee’s perspective, all of this documentation could look a little like a pyramid or maybe even a little like steps. 😎

The first step is understanding the process with regard to a certain area of the business.

The second step, procedures, or SOPs as we like to call them, is more detailed and often may contain additional information over and above a process.

The third step is workplace instruction which describes the work to be performed. They include specific instructions necessary to complete the task. For example bullet points on how to answer a customer query or how to complete a form.

Your process, SOPs and work instructions formula

The best way we’ve found is to think about it in terms of why then (who + what + when) and then how.

Process = Why and the BIG picture?

SOPs = Who, what, and when?

Work Instructions = How exactly?

Don’t worry, it isn’t maths but it is a simple formula for getting things right and optimizing efficiency in a scaling business.

SOP vs. Work Instructions vs. Process: what are the differences?

Process:

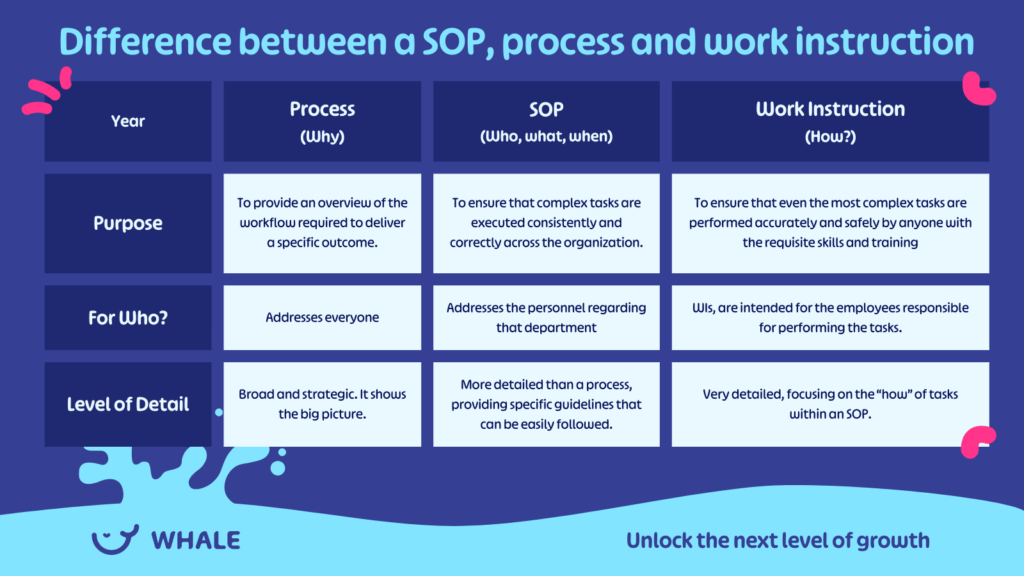

- Definition: A process is a high-level description of a series of actions or steps taken to achieve a particular outcome. It focuses on what needs to be done, along with the sequence of activities.

- Purpose: To provide an overview of the workflow required to deliver a specific outcome. It defines the start and end points, the inputs and outputs, and the general flow of tasks.

- Detail Level: Broad and strategic. It shows the big picture without detailing every step.

Standard Operating Procedure (SOP):

- Definition: An SOP is a set of written instructions that document a routine or repetitive activity followed by an organization.

- Purpose: To ensure that complex tasks are executed consistently and correctly across the organization. It focuses on the methodology and often includes who will perform the task, when, and under what criteria.

- Detail Level: More detailed than a process, providing specific guidelines that can be easily followed. It often includes the steps necessary to complete tasks that are part of the broader process.

Work Instruction:

- Definition: A work instruction provides detailed, specific actions and steps to perform a particular task. It is the most detailed of the three and is often task-specific.

- Purpose: To ensure that even the most complex tasks are performed accurately and safely by anyone with the requisite skills and training. It is often used in training and ensuring quality control.

- Detail Level: Very detailed, focusing on the “how” of tasks within an SOP. It often includes exact specifications, measurements, and other data necessary for performance.

Process starts with why

To be successful, business processes must contain four different elements; defined, repeatable, valuable, and flexible.

Process is a high-level document that details the business process. It’s an overview of why you exist or why that process exists.

Let’s imagine you own a travel company. Your business process is to help people travel. Your team looks for the best deals and destinations and offers them to your customers.

Once the customer pays, the transaction is complete with additional support offered over travel periods.

That’s the process.

Business processes are critical to every business and can help you save time and money while ensuring that you provide consistency to customers.

Your process checklist ✅

- Explains why

- Shares goals

- Lists objectives

- States accountability

SOPs tell you who, what and when

Standard operating procedures (SOPs) are comprehensive documents that outline the step-by-step instructions for carrying out a process or task within an organization. These procedures serve as a guide for employees, ensuring that they follow a standardized approach when performing their duties. SOPs are typically created by subject matter experts and are designed to provide consistency, efficiency, and quality in operations.

SOPs contain key information such as the purpose of the process, the roles and responsibilities of individuals involved, the sequence of steps to be followed, and any specific instructions or precautions. They may also include references to relevant documents, forms, or templates that are necessary for executing the process.

The primary purpose of SOPs is to achieve uniformity in operations, regardless of the individuals performing the tasks. By providing a clear framework, SOPs reduce the risk of errors, ensure compliance with industry standards and regulations, and enable effective training and onboarding of new employees. Additionally, SOPs facilitate continuous improvement by allowing organizations to analyze and refine their processes over time.

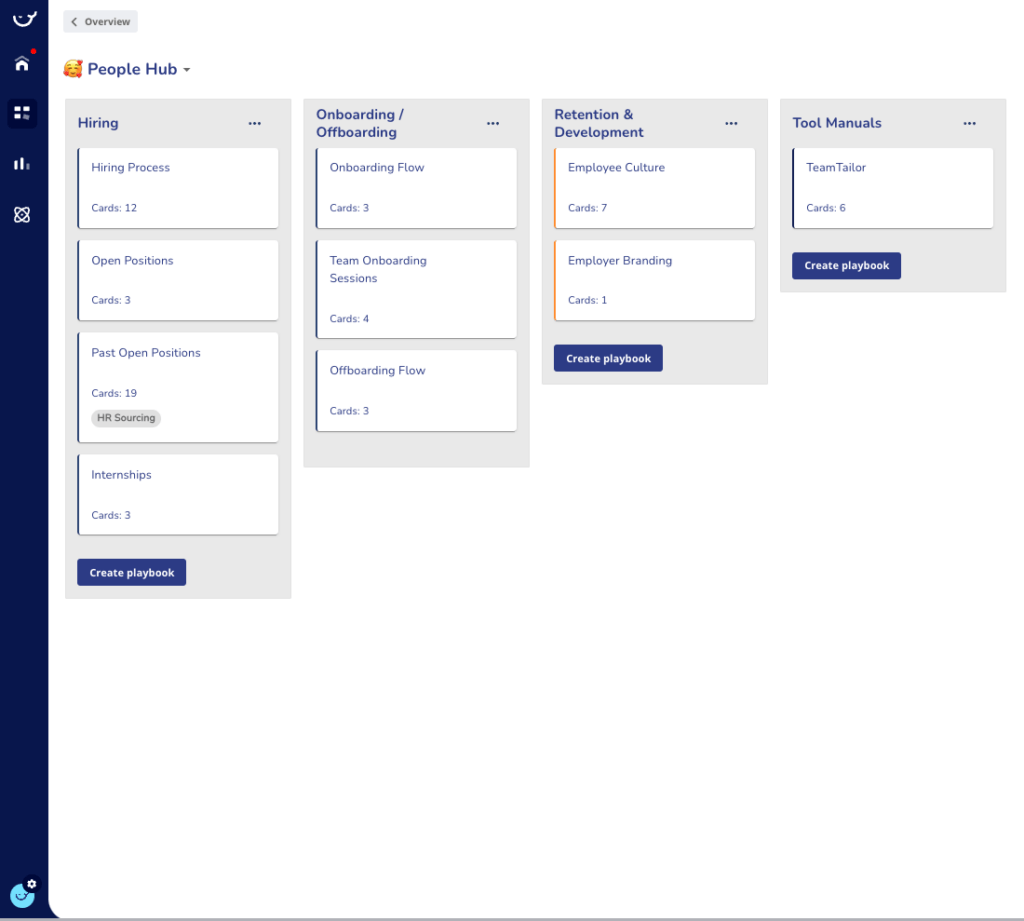

Also called Standard Operating Procedures, SOPs can be implemented across every department, ensuring that work is completed correctly and efficiently.

In the case of the above example at the travel company, the SOPs would cover aspects such as team HR procedures, and customer service procedures. Whilst workplace instructions would detail how to conduct a call with a prospective customer or how to complete a refund for a customer.

We spoke to Xavier Chang, Business Process Consultant at XC Consulting, and his experience utilizing SOPs with clients.

When considering WHAT SOPs to create Xavier references Gino Wickman’s, hit business book Traction

“when documenting the processes, you should follow the 20/80 rule. That means document the 20 percent that produces 80 percent of the results. The trap many organizations fall into is wasting valuable time trying to document 100 percent of everything.”

He says, instead of trying to get SOPs perfect, rather get them done and fit for purpose.

Your SOP checklist ✅

Your simple SOPs checklist ✅

- Details how to do the steps outlined in the process

- Tells who does the steps in the process

- States when each step in the process gets done

Work instructions tell you exactly how

While SOPs provide a high-level overview (although more detailed than process, work instructions (WIs) focus on the specific tasks and actions required to complete that process. WIs provide step-by-step guidance to employees, detailing the exact procedures they need to follow to carry out their assigned tasks effectively.

Unlike SOPs, WIs are more granular and task-oriented. They break down the process into smaller, manageable steps and provide additional information such as specific equipment or tools to be used, safety precautions, quality standards, and any other relevant details. WIs are typically created for individual tasks within a larger process, ensuring consistency and accuracy in execution.

WIs are particularly useful in complex processes where multiple tasks need to be performed by different individuals or teams.

By providing clear instructions, WIs minimize the risk of confusion or mistakes, improving efficiency and reducing the likelihood of rework. They also serve as a valuable training resource for new employees, allowing them to quickly understand and perform their tasks correctly.

A work instruction is a written document that provides clear and precise steps to carry out a single instruction.

Clear and concise workplace instructions;

- ✅ Guarantee a consistent outcome out of common tasks or projects, no matter who the task owner is

- ✅ Can help reduce errors and/or workplace accidents

- ✅ Save time

- ✅ Facilitate continuous improvement

Your Workplace Instructions checklist ✅

- Title and short description of the task

- Objectives or expected results

- Purpose of the task

- Scope of the task

- Tools or skills required

- Safety requirements

- Step-by-step instructions for the task

- Expected outcome for each step and what to do in case of emergency/things-gone-wrong

Best practices for using SOPs, and work instructions

To maximize the benefits of standard operating procedures (SOPs) and work instructions (WIs), consider the following best practices:

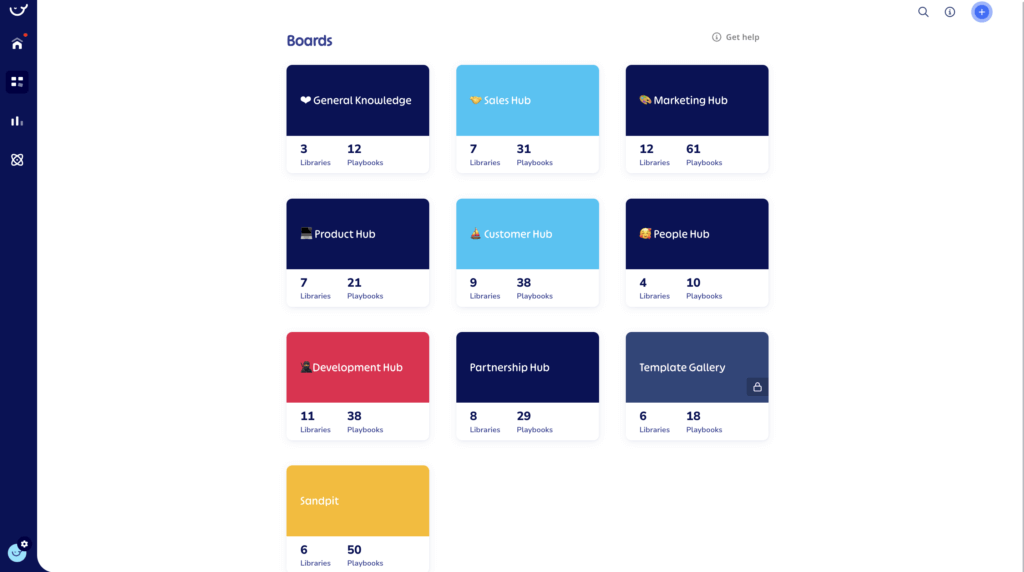

- Use SOP Software to make your life easier! It’s going to save you a lot of time and effort.

- Keep them up to date: Regularly review and update SOPs and WIs to reflect any changes in processes, regulations, or best practices. Ensure that employees have access to the latest versions.

- Make them easily accessible: Provide employees with easy access to SOPs and WIs through a centralized repository or digital platform. Ensure that the documents are searchable and organized.

- Train employees on usage: Conduct training sessions to familiarize employees with the purpose and usage of SOPs and WIs. Emphasize the importance of following these documents for consistency and quality.

- Encourage feedback: Create channels for employees to provide feedback and suggestions on SOPs and WIs. Actively seek input to improve the clarity and effectiveness of the documents.

- Promote continuous improvement: Use SOPs and WIs as a foundation for process improvement initiatives. Encourage employees to identify areas for enhancement and propose changes.

- Integrate with performance management: Align the usage of SOPs and WIs with performance management systems. Consider incorporating adherence to these documents as part of employee evaluations.

- Regularly communicate updates: Whenever there are updates or changes to SOPs or WIs, ensure that employees are informed. Communicate the reasons for the changes and provide training if necessary.

Following these best practices will help organizations optimize the usage and benefits of SOPs and WIs, driving efficiency and quality in their operations.

Process, SOPs, and work instructions summary

| Process | SOPs | Work Instructions |

| Addresses everyone | Addresses the personnel regarding that department | Addresses the personnel regarding that specific job function |

| Company-wide | Specific or various departments | Specific or various people |

| Very general | Focuses on the instructions for getting a specific job done |

Bottom line

The quick summary is that;

- Processes are about the sequence of steps.

- SOPs describe how these steps should be executed.

- Work Instructions tell you exactly how to perform each step in detail.

By distinguishing these elements, organizations can ensure clarity and efficiency in task execution, training, and compliance across all levels.

Want to know more? Make sure you download our Ultimate Guide to SOP and Process Documentation

Or simply sign up for a free account on Whale. (Yes, forever free!)

FAQs about SOPs, and work instructions

Where to start with process, SOPs, and work instructions? Don’t panic! 🤯

We often get asked the difference between process, SOPs, and work instructions which is why we wanted to write this piece.

The next question we’re often asked next is “how on earth do I get this done?”

First step. Don’t panic!

Often in start-ups and scale-ups this information isn’t separate and that’s okay, however as you scale, it may be more useful to separate this out.

You may want to sign up for our FREE process challenge to help you get this done?

Or check out 10 Mistakes to avoid in documenting your processes.

What should a work instruction include?

- Title and short description of the task

- Objectives or expected results

- Purpose of the task

- Scope of the task

- Tools or skills required

- Safety requirements

- Step-by-step instructions for the task

- Expected outcome for each step and what to do in case of emergency/things-gone-wrong

What are the different types of SOPs?

Why are there different types of SOPs? It is the same reason as there are different types of cars – each one has its own style and purpose, and is suited for different use cases.

Step-by-Step SOPs: Think of them as the recipe for your favorite dish, providing detailed, sequential steps to whip up a perfect outcome every time.

Hierarchical SOPs: These are the LEGO instructions of SOPs, breaking down tasks into main steps and sub-steps. Ideal for tasks with layers of complexity that need some unpacking.

Flowchart SOPs: Picture a treasure map, guiding you through tasks with decision points and pathways. These are perfect when choices need to be made during the process.

Checklist SOPs: Your grocery list for getting things done. Simple, tick-off tasks ensure nothing is missed, keeping things straightforward and tidy.

Key Terms & Further Reading on SOPs, and work instructions

Get documenting & training NOW

What is your greatest challenge?

SOP & Process Documentation

Use Whale to create SOP & Process Documentation and centralize everything in an easily accessible single source of truth.

Employee Onboarding & Training

Whale is the fastest way to get your team aligned. Discover how Whale boosts team performance and ensures new hires excel from the get-go.

Companies on EOS ®

Whale is the all-in-one system for teams running on EOS® to help document your processes, train your teams, and build a foundation for growth.